Pouring a concrete slab on a slope is a highly technical job. Under different working conditions, the concrete slope construction scheme is also different. For example, when the slope is small, the construction area is relatively small, there is no high requirement for concrete, and you only need to keep accurate formwork support to easily complete the work. However, when the surface area is relatively large (for example, concrete slabs of several hundred square meters), the small slope will be very difficult to control. There are also some concrete slopes with large slopes. In addition to selecting the correct concrete slump, preparation for a response should be done, and appropriate construction equipment should be used.

Below we will explain the precautions and best methods for pouring a sloped concrete slab.

How To Choose The Slump For Concrete Slope

The concrete slump is crucial for pouring sloped concrete slabs. If you use high-slump concrete, the concrete will be too fluid to hold the slope. However, if the concrete has a too low slump, it will make your work more difficult.

How To Test Slump?

The test method of slump: with a φ100mm upper mouth, φ200mm lower mouth, 300mm high horn shape slump bucket, filling concrete three times, each time after filling with a hammer along the barrel wall from the outside to the inside hit 25, after compaction, wipe flat. Then pull up the bucket, concrete because of its weight slump phenomenon, with bucket height (300mm) minus the height of the concrete peak after collapse, called slump. If the difference is 10mm, the slump is 10.*The measurement standards of each country and even region are different. For specific measurement methods, please refer to the local concrete standards.

So, if a professional concrete supplier provides your concrete, you need to tell them your working conditions, and they will choose the right kind of concrete for you. If you want to know the specific data or mix the concrete yourself, you can refer to our suggestions below.

Slope: Less Than 10°

For some concrete slab works with a low slope (within 10°), you can use a concrete slump of more than 3 “. But there are small projects, like stairs and ramps for some homes and small terraces. High-slump concrete can also be used even if the slope is more than 10°. You need to set up the formwork and then use a hand screed to scrape the concrete flat. You can have good control of the slope.

Slope: 10° – 30°

For a concrete slope with a large slope (slope greater than 10° and less than 30°), the selection range of general slump is 2 “-3”.

Slope: >30°

For slopes over 30° and less than 45°, choose concrete with a drop of 1″-2″. Shotcrete or double forming can be used when gradients are greater than 45 degrees or even vertical (such as tunnel walls or guard slopes).

How To Pour Sloped Concrete

In this section, I will introduce three slop paving methods, explaining how they apply to everyday work and providing insights on paving large slopes and wide areas of concrete screeds.

The first method is suitable for constructing small residential concrete ramps or slope, and it is quite straightforward. The other two methods focus on larger angle concrete slope constructions and extensive areas concrete slope, primarily introducing the 2 new equipment application that simplify these construction processes.

Home Ramps, Diy slope Concrete Slab

As we mentioned above, for some small (domestic) concrete projects. You need to set up the formwork and then use the hand tools to complete the slope.

Ensure that the moisture content of the concrete is balanced, avoiding both excessive wetness and dryness. We recommend starting with a slump value of 3 to 4 inches to ensure that the concrete retains its shape.

Pouring Concrete: During the pouring process, the concrete must maintain sufficient dryness to prevent sinking on slopes. Overly wet concrete can lead to instability in shape, while excessively dry concrete can make the construction process difficult.

Leveling the Concrete: Use a screed to level the surface of the concrete. When dealing with steep slopes, there is a tendency for the concrete to sink, so careful handling is necessary to ensure an even surface.

Employ a bull float on the surface of the concrete for further leveling. Operate slowly and steadily to avoid causing the concrete to sink.

Concrete Surface Treatment: After leveling the concrete, use a broom to treat the surface, increasing friction to prevent slipping.

Maintaining balance during construction is crucial, especially when working on steep slopes. Once completed, the concrete surface will exhibit a uniform broom finish, ensuring safety while clearing snow in winter.

Roller Screed Slope

In addition to the use of viscous concrete with a low slump (as mentioned above), it is also important to note that concrete levelling equipment with strong vibrations should not be used. Because too much vibration will make it difficult for concrete to hold down and cause downward flow. We recommend that you use a roller screed to level these concerts. In addition, you also need to consider whether the construction personnel on both sides of the construction can walk smoothly. You can use wood or scaffolding to set up a ladder for walking.

High Angle and Large Area Concrete Slope (2 NEW WayS)

In some engineering projects, the concrete slopes we encounter are often significantly more challenging to construct than residential driveways. For instance, in dam projects, many of the slopes exceed 30 degrees, making it easy for the concrete to slide or collapse during construction. Additionally, large parking lots require a few centimeters of elevation change over distances of several dozen meters to ensure proper drainage. Successfully executing these projects necessitates the use of effective equipment, such as Concrete Canal Screed Pavers and laser slope screeds.

Concrete Canal Screed Paver

This is a newly developed concrete slope machine designed specifically for paving large concrete slopes. It allows contractors to complete steep slope paving projects at a lower cost.

The Concrete Canal Screed Paver Machine by Hiking Machinery is a custom-designed product specifically built for paving concrete on slopes and canals. With its unique design and superior performance, this machine stands out among similar products. Unlike traditional equipment, it addresses the common issues of concrete slipping and inadequate compaction in steep slope projects.

Equipped with a large vibration motor and an extra-wide vibrating compaction plate, this machine significantly improves concrete compaction and prevents the material from sliding during construction. For projects with steeper slopes, users can opt to add a working platform, enabling workers to assist with construction more conveniently.

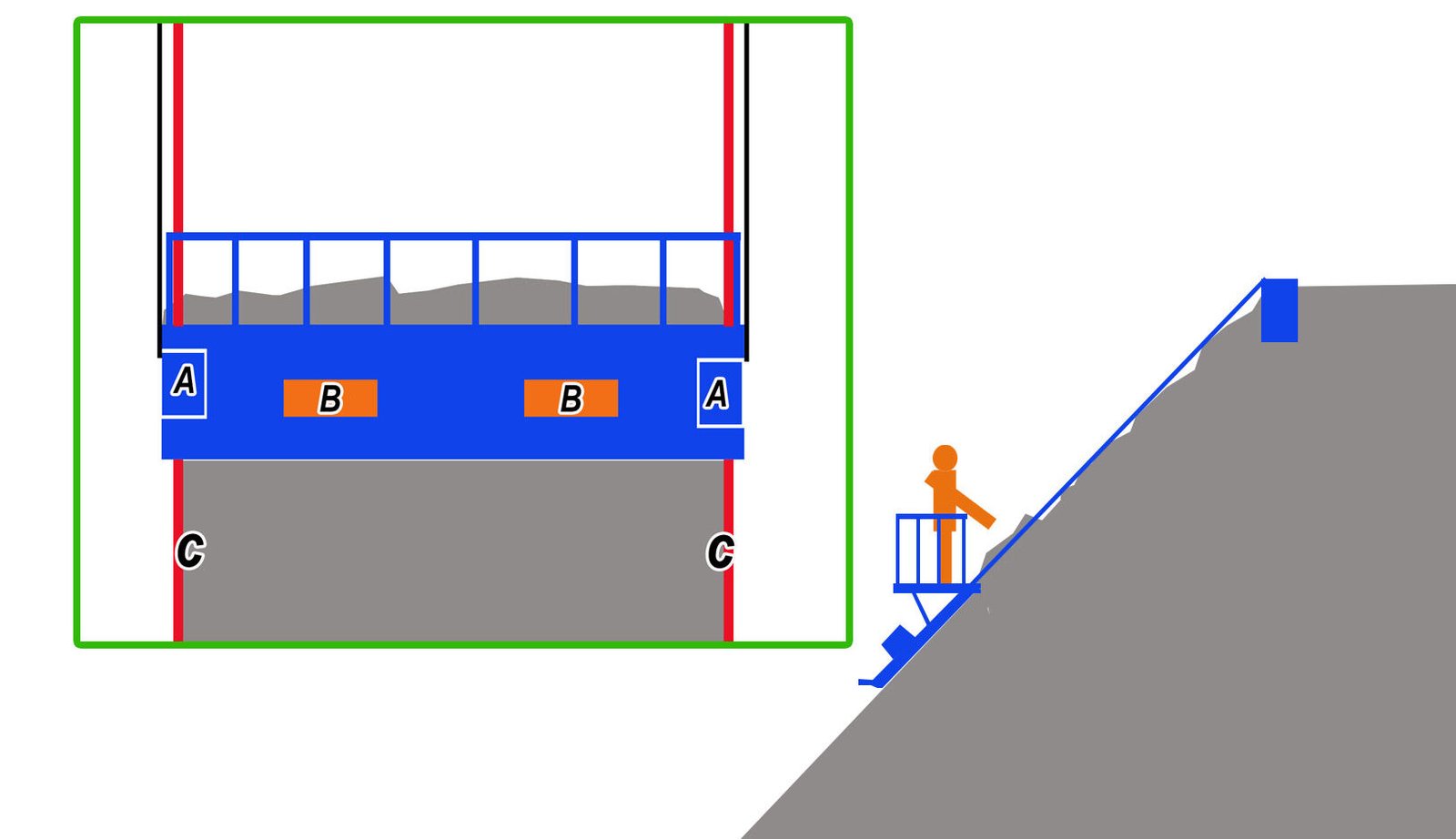

The working principle is illustrated below:

In the diagram, C represents the formwork set up on the slope; A is the winching equipment for the steel cables on both sides of the machine. The steel cables are fixed at the top of the slope, and when the winches on either side of the machine are activated, they pull the steel cables, dragging the machine upwards along the formwork. B is the machine’s vibrating motor, which helps compact the concrete on the slope.

For projects with steeper slopes, we have also designed a working platform, allowing workers to stand on the machine to assist with the paving process.

The concrete canal screed paver is versatile and can be widely used in various types of steep slope concrete paving, such as for canals and ditches.

Laser Concrete Screed Slope

For some large areas concrete slopes (small angle), such as some industrial floors or large car parking. These small slopes of the floor can be formworked many times fromwork and then scraped flat using a power screed. But this construction, the difficulty will be relatively large. Currently, the best way is to use a laser screed to automatically make these concrete slopes. In this way, you only need to set up the formwork at the edge of the working range once, and the concrete laser screed can automatically level according to the slope you set. This method can save a lot of manpower.

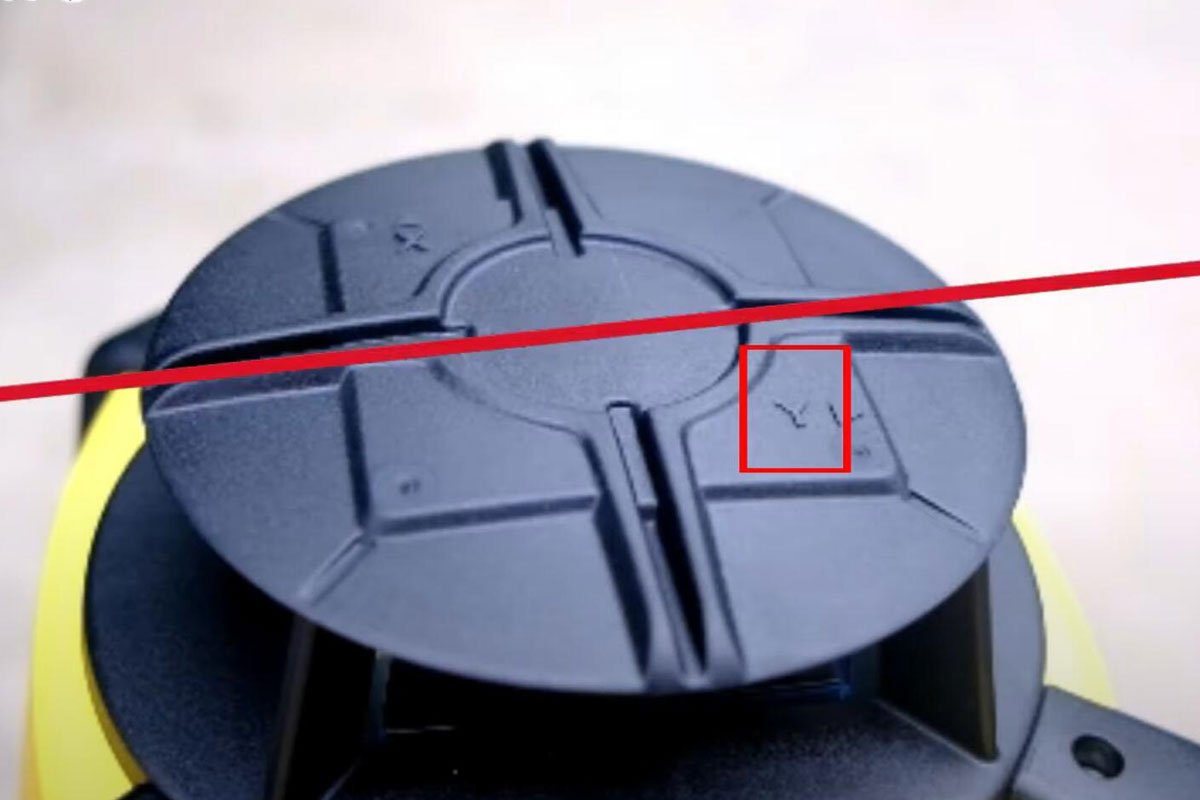

- Set Up the Laser Emitter: Mount the laser emitter on a tripod, ensuring it is roughly aligned with the X and Y axes. Turn on the laser emitter and enter the laser plane angle setting mode.

- Adjust the Laser Plane Angle: Use the appropriate buttons to adjust the laser plane angles for the X and Y axes. The angle can be changed using the up and down buttons.

- Determine the Reference Point: Identify the reference point (zero point) and place the receiver at this location, ensuring the receiver’s indicator light is on.

- Calibrate the Receiver: Adjust the position of the receiver until its reading is zero. Ensure that the readings of the laser receiver match those of the laser emitter.

- Begin Leveling: Once the equipment is set up, you can start using the laser leveling machine to level the concrete slope.

- Monitor and Adjust: During the leveling process, monitor the receiver’s readings to ensure the slope meets the required specifications. Adjust the laser plane angle as needed.

This process outlines the steps for effectively using a laser emitter to create a concrete slope, ensuring precision and accuracy throughout the leveling operation.

Conclusion

From our article, I’m sure you already know some about how to pour a concrete slab on a slope. We must pay attention to the concrete slump in constructing these concrete slopes. And the choice of the right tools is also very important. At the same time, the construction site supporting facilities must be prepared. This way, you can easily complete a sloped concrete slab.