Before you embark on a core drilling project, how familiar are you with this technique? Core drilling primarily involves using equipment to drive a hollow drill bit into a specified location to extract cylindrical samples of concrete or other materials. These drilled holes not only provide pathways for various pipelines but also allow the extracted cores to be used for assessing the quality and performance of the structure. In this article, we’ll explore the following topics in detail:

- The definition and specific uses of core drilling

- How to choose between dry and wet drilling methods

- An overview of common core drilling methods and equipment

- Tips for simplifying core drilling operations

By reading this article, you’ll gain a comprehensive understanding of all aspects of core drilling, along with practical tips to make the process easier.

Let’s get started!

What Is Core Drilling?

Core drilling is a technique that involves using specialized equipment to drill cylindrical samples, known as cores, from solid materials. This process is commonly applied in construction and civil engineering to extract samples from hard materials like concrete, rock, and masonry. The equipment used for core drilling typically includes a hollow drill bit, often embedded with diamond or other hard materials, to efficiently cut through high-strength materials.

The primary purpose of core drilling is to obtain core samples for various analyses and tests, such as evaluating the strength, density, and porosity of concrete. These samples play a crucial role in quality control, structural assessment, fault diagnosis, and ensuring the safety of engineering projects. Additionally, core drilling can create openings in walls, floors, or other structures to facilitate the installation of pipes, cables, or other utilities.

The advantage of this technique lies in its precision and minimal destructiveness, allowing necessary samples to be extracted or pathways created without compromising the structural integrity. Core drilling can be performed in different environments and conditions, including both dry and wet drilling, depending on the nature of the material being drilled and the requirements of the job site.

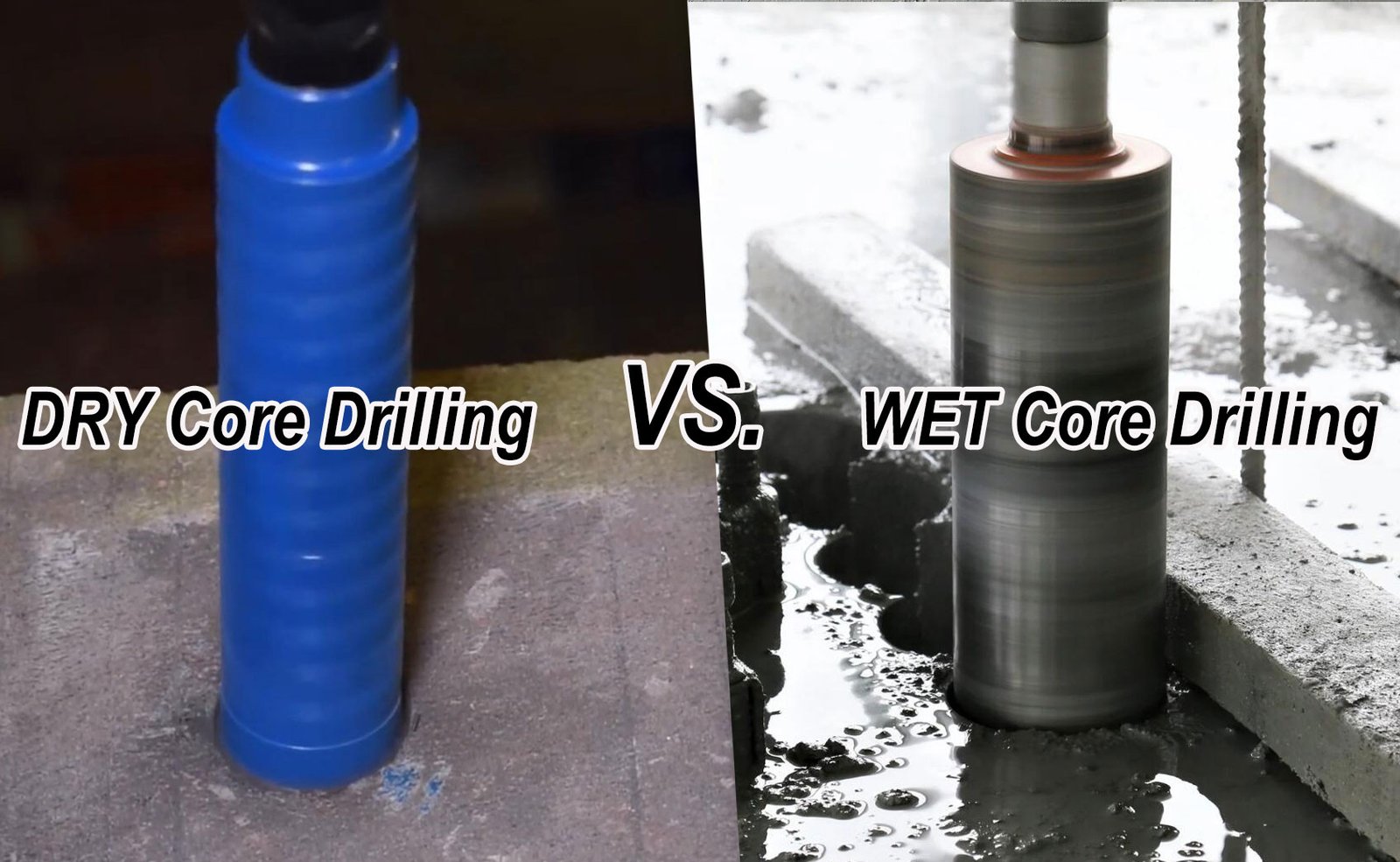

Dry vs. Wet Core Drilling: What’s the Difference?

As mentioned earlier, core drilling can be done using either dry or wet methods. But what are the differences between these two approaches, and how should you choose the right one?

Firstly, it’s important to know that both drilling methods generally use the same drilling machine, with differences primarily in the type of drill bit used—some drill bits can even be used for both dry and wet drilling. Dry drill bits require no additional cooling, relying on air to dissipate heat, while wet drill bits require water for cooling.

To help you make an informed decision, we’ve created a detailed comparison chart outlining the pros and cons of each method.

| Feature | Dry Core Drilling | Wet Core Drilling |

|---|---|---|

| Advantages | ||

| No water source needed | Does not require a water cooling system, suitable for environments without water | Requires water cooling, but reduces dust |

| Less cleanup required | No slurry from water, less cleanup needed | Water cooling reduces dust, improving air quality |

| Simple operation | Portable equipment, easy to operate, suitable for small tasks | Water cooling extends drill bit life, improving drilling efficiency |

| Suitable for special materials | Suitable for materials that cannot withstand water, like wood or some composites | Suitable for hard materials, like concrete and stone |

| Disadvantages | ||

| Generates a lot of dust | Produces a lot of dust, requiring control and cleanup | Requires a water source, and the site may become slippery |

| Heat accumulation | Drill bit easily overheats, affecting efficiency and lifespan | Increases cleanup work, as the site may have leftover slurry |

| Limited drilling depth | Depth is limited, especially in hard materials | Can achieve greater drilling depth |

| Lower drilling efficiency | Lack of cooling slows down drilling speed | Higher equipment cost, requires water pump and cooling system |

How to Make Core Drilling Easier

We’ve broken down the core drilling process into 4 steps and provided some tips to simplify your operations, ensuring you understand the process better.

Preparation

Before drilling, it’s essential to determine the exact drilling location and hole diameter, ensuring there are no potential obstacles like rebar, water pipes, or electrical wires in the area. If precise drawings are not available, using detection equipment to pre-scan the area is crucial to avoid damaging these structures.

Choosing the Right Drill Bit and Equipment

Typically, diamond drill bits are used for concrete core drilling to effectively cut through concrete and create clean holes. As mentioned earlier, dry and wet drill bits are available, and if you’re unsure which one to choose, refer to our comparison chart to help you select the appropriate bit.

To ensure drilling accuracy, the core drill stand should be securely fastened to the concrete surface. When drilling on vertical walls, using a vacuum base or anchor bolts to stabilize the equipment is essential to avoid errors caused by equipment movement during operation.

Our new core drilling equipment make the core drilling process easier, making it easy to secure the coring drill machine in place.

Core Drilling Process

When starting to drill, it’s particularly important to use water to cool the drill bit. This reduces friction and dust, and prevents the bit from overheating and getting damaged. Begin by slowly starting the core drill, gradually increasing pressure until the bit smoothly penetrates the concrete. Throughout the drilling process, maintaining a steady flow of water is crucial to keep the bit in optimal working condition.

As the bit fully penetrates the concrete, gradually reduce the pressure and eventually stop the core drill. You can then carefully remove the core drill with stand and bit and extract the concrete core, especially if you need to preserve the sample. After drilling, inspect the hole’s quality and dimensions to ensure they meet the expected requirements, avoiding issues during subsequent use.

Cleanup

Finally, cleanup is just as important as the drilling itself. The wastewater, dust, and debris generated during drilling should be promptly cleaned up to maintain a tidy worksite. Additionally, clean and inspect the drill bit and core drill to ensure they are undamaged and perform any necessary maintenance or replacements. This not only extends the equipment’s lifespan but also prepares it for future use.

By mastering these techniques, you can carry out core drilling operations more efficiently, ensuring precision at every step.

Conclusion

In this article, we’ve delved into the definition, uses, method selection, and operational tips for core drilling. We hope that through this content, you’ve gained a comprehensive understanding of core drilling, whether in practical application or theoretical study, and that it will help you master this technique more effectively.

If you encounter any other issues or challenges in practice, feel free to leave a comment. We look forward to engaging in further discussions with you.