Do you want to excel at constructing roads, drainage systems and floor slopes? Don’t miss out on this comprehensive guide to Slope Laser Level technology! Discover how a Slope Laser Level can effortlessly create precise single and dual slopes. Watch step-by-step demonstrations of slope laser level settings and learn how to achieve complex site control in just a few simple steps. Whether you’re a beginner or an expert, our expert guidance will help you get up to speed quickly, avoid common mistakes, boost efficiency and ensure precision. You can also explore advanced laser screeding solutions for concrete floor slopes that showcase the latest automation and smart technology trends in the industry. Are you ready to begin your journey in precision slope construction?

What is a slope laser level?

It is a surveying instrument that creates sloped laser planes based on horizontal references. This advanced tool uses an internal motor to rapidly rotate the laser through 360°, producing a full light disc. Operators can use the control panel to input tilt angles for both the X-axis and Y-axis, typically within a range of ±5°. The Slope Laser Level then automatically transforms this light disc into single or dual slope planes. This technology is essential for construction projects that require precise grading, such as roads, drainage systems and site grading.

Coordinate Axis System

To ensure accurate control of laser plane inclination, Slope Laser Level systems utilise a user-friendly coordinate system.

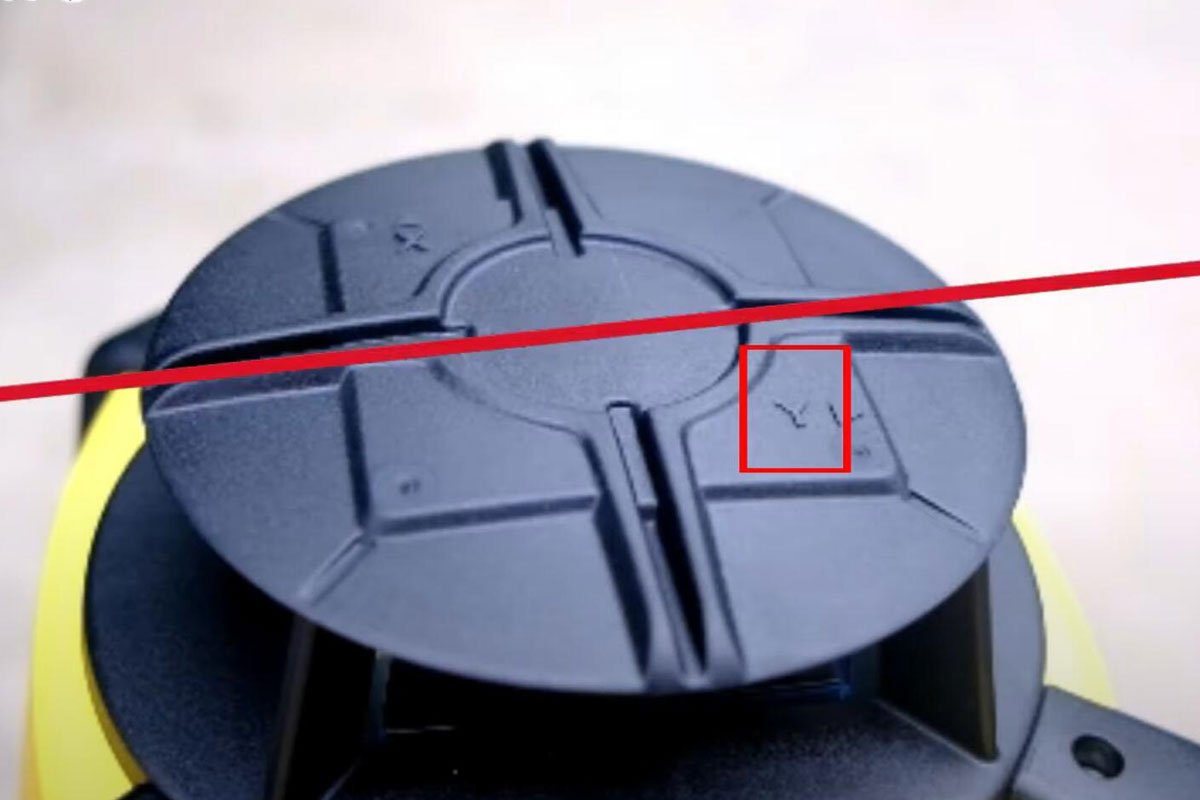

- X-axis: A directional line passing through the laser’s rotation centre point.

- Y-axis: Another directional line passing through the rotation centre point that is perpendicular to the X-axis. These two perpendicular axes intersect at the rotation centre, working together to determine the three-dimensional tilt orientation of the laser plane in space.

Tilt Angle Adjustment Features

The flexible angle adjustment system enables Slope Laser Level equipment to address challenging terrain and drainage needs effectively, significantly enhancing construction accuracy and efficiency.

How to Set Up A Slope Laser Level

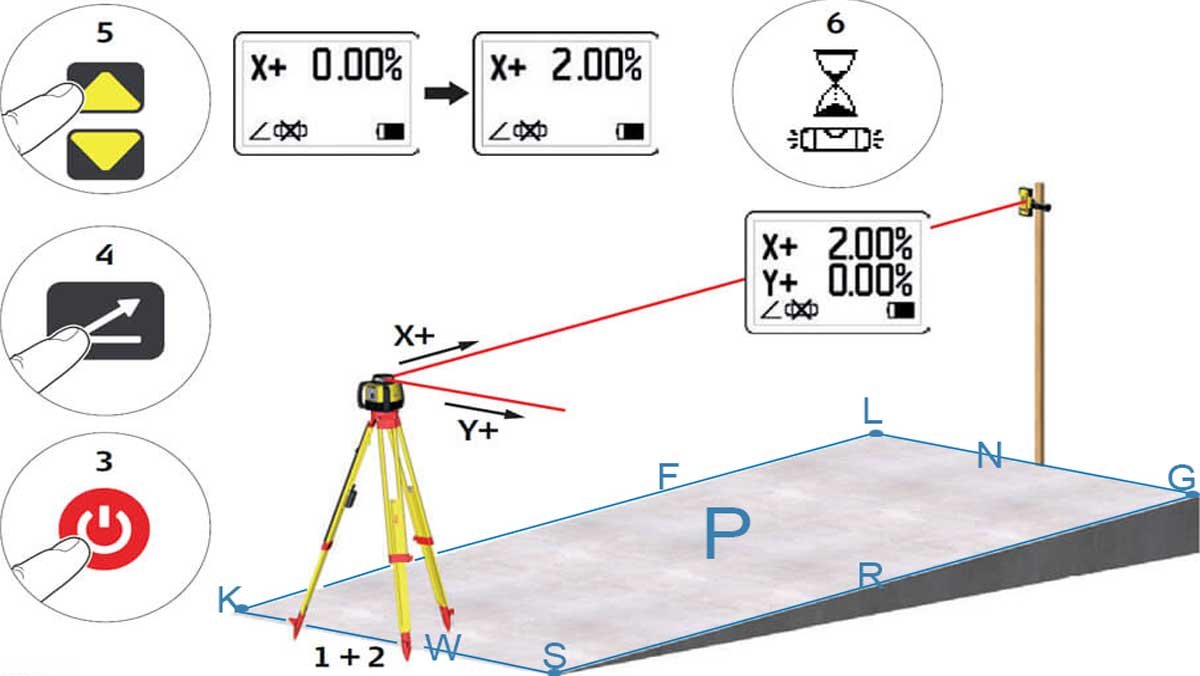

Now that we have covered the fundamentals of the Slope Laser Level, let’s learn how to configure your equipment for specific grades. The process is quite simple. In this section, we will demonstrate both single and dual slope setup methods using the Leica Rugby 600 series Slope Laser Level, helping you master these techniques quickly.

- Slope Laser Level: Operators can configure the tilt angles of the X- and Y-axes independently, typically within a ±5° range.

- Single Slope Laser Mode: Only the X-axis angle is adjusted, while the Y-axis remains level. This mode is ideal for straightforward, unidirectional slope construction, such as linear drainage channels or single-direction sloped roadways, as the laser plane only tilts in one direction.

- Dual Slope Laser Mode: Both the X-axis and Y-axis angles can be adjusted simultaneously. This allows the laser plane to create a compound inclination, making it suitable for developing complex slopes, such as those required for car park drainage, sports field construction or areas requiring multidirectional drainage systems.

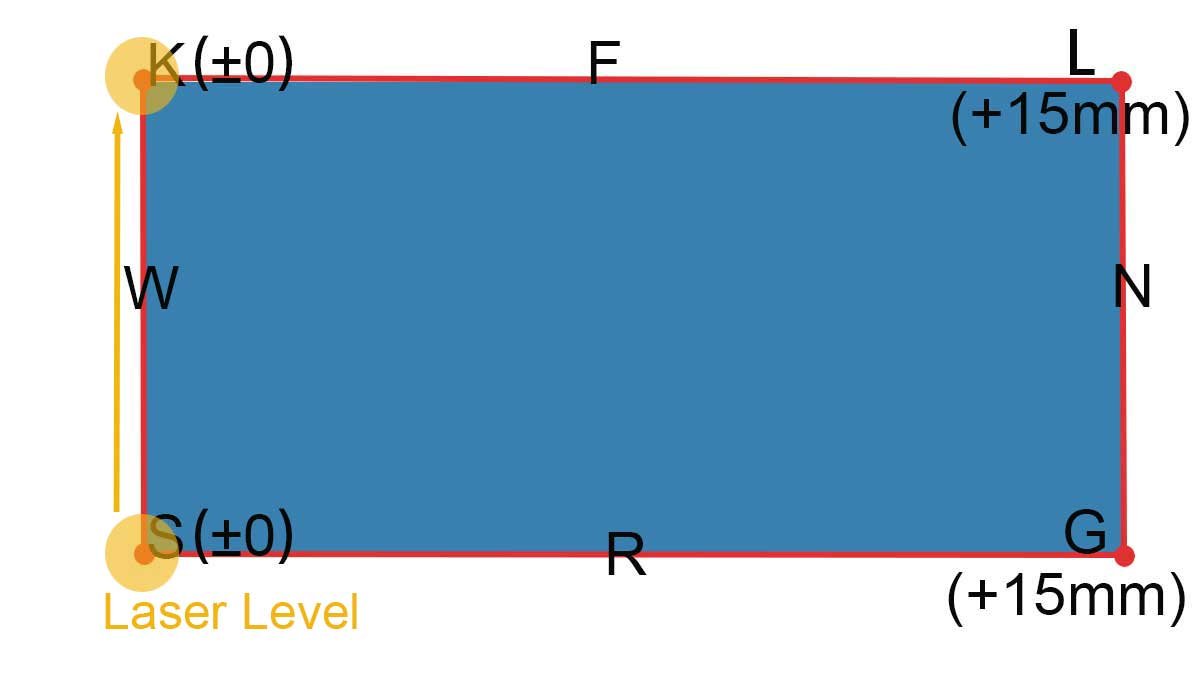

Point Selection and Alignment: Position your Slope Laser Level so that the X-axis is parallel to the intended slope direction. When creating the slope surface P for a rectangular area, ensure that the X-axis is aligned parallel to P, while the Y-axis should be either parallel to or coinciding with the baseline W.

Single Slope Laser Level

Rough Leveling: Slope Laser Level instruments are designed with automatic leveling capabilities; however, their leveling range is typically limited to ±5°. To ensure accurate measurements, manually level the instrument using the tripod leg screws until the circular bubble is centered.

Important note: After turning on the device, the laser head will not rotate immediately. Your Slope Laser Level will first initiate its auto-leveling program, which takes about ten seconds to complete before the laser scanning begins.

Grade Setting Process: Position a staff with a receiver vertically at the surveyed reference point marked as ±0. Adjust the receiver up or down until the laser signal is centered. Next, move the staff vertically to the surveyed high point or low point, gradually adjusting the slope value on the X-axis until the receiver is centered once more. Once this process is complete, your Slope Laser Level will establish the desired grade along the X-axis.

Dual Slope Setup

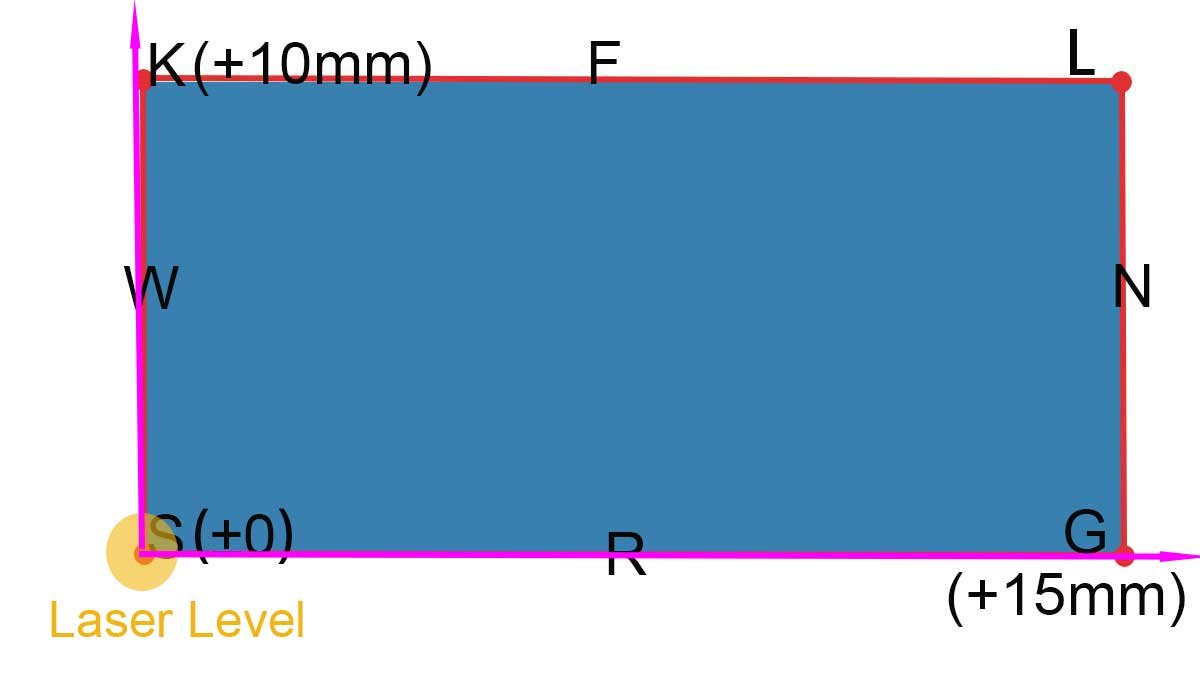

Precise Instrument Placement: Position your Slope Laser Level so that both X and Y axes perfectly align with two adjacent sides of the rectangular area. The center of the instrument should align with the intersection point S of these two sides(R and W).

Rough Leveling: Use the same method as the single slope setup, but achieving coordinate alignment while leveling the tripod is somewhat more challenging.

Grade Setting Process: Start by centering the ±0 reference point on the staff as you did previously. Next, select reference points along both the X-axis and Y-axis alignment lines. Sequentially position the receiver at each point, adjusting the X-axis and Y-axis slope values accordingly until the receiver is centered at both locations. Once complete, your Slope Laser Level forms the required bidirectional slope with precision.

Laser Screed Concrete Slope Applications

In concrete floor construction, laser screed technology is commonly employed in conjunction with Slope Laser Level systems for large-scale sloped applications, such as car parks and industrial floors. Such projects often cover vast areas with slopes that typically do not exceed 3°(We have previously published articles providing detailed information on pouring concrete slopes at larger angles. Please refer to the following: How to pour concrete slope). Achieving the necessary precision in these cases using traditional formwork control methods is highly challenging.

Slope laser levels for laser screed applications provide high-precision levelling in a single pass, enabling fast, automated construction while accommodating both single and dual slopes. This technology has become an established industry standard.

We have created a video that explains how to do this in detail:

Conclusion

This comprehensive guide thoroughly examines the core technology and practical applications of the Slope Laser Level. We have explained the principles of the X/Y-axis coordinate system, shown how to set up slopes accurately using single and dual methods, and provided operational guidance for using the Leica Rugby 600 series Slope Laser Level. The article also covers advanced Laser Screed applications for concrete slopes, showcasing the latest automation trends in road, drainage and flooring construction.

Whether you are a beginner or an expert, this guide will help you to master Slope Laser Level technology and significantly improve construction efficiency and accuracy. This expertise will be beneficial for various construction applications requiring precise grade control.

If you found this technical guide helpful, please share your experiences or questions in the comments below, and pass it on to other construction professionals who might benefit from it! Let’s work together to advance Slope Laser Level construction technology!