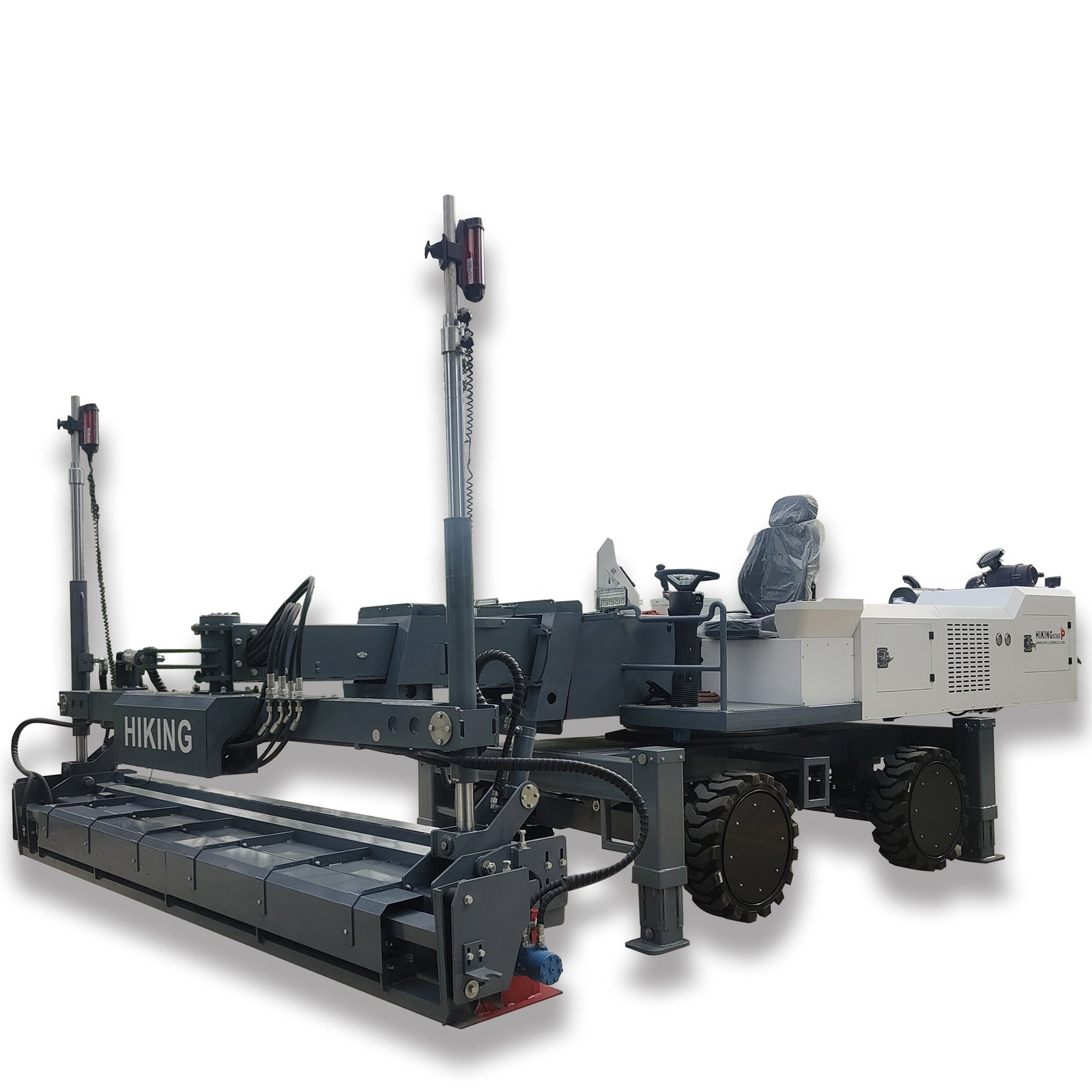

S360-P Boom Laser Screed (4M & 63KW)

$160,000.00

The S360-P Boom Laser Screed is an upgraded product based on the S360 by HIKING. This machine is equipped with a more powerful imported Yanmar engine, delivering 63KW of power. The screed head width has been upgraded to 4 meters, and the boom length extends to 6 meters, significantly enhancing production efficiency. The machine features one-touch leveling and one-touch retraction functions, with the capability to switch between four-wheel and two-wheel steering. The work platform can rotate 360 degrees, offering excellent maneuverability and operability. Despite its compact design, the S360-P ensures flexibility in low and confined spaces.

Product Overview

The HIKING S360-P Boom laser screed is the ultimate solution for contractors aiming to achieve precise and efficient concrete levelling. Featuring a screed head width of 4 meters and a boom length of 6 meters, the machine boasts high production efficiency. It offers the flexibility of switching between four-wheel and two-wheel steering, and its working platform can rotate 360 degrees, ensuring excellent maneuverability. For ease of operation, it is equipped with features like one-button pull back and one-button leg leveling, making its operation unprecedentedly simple. Powered by a Yanmar turbocharged diesel engine and designed with a smaller and lower profile, the machine ensures flexibility in tight and low-clearance spaces.

Specifications of S360 Boom Laser Screed

| Type | S360-P (Plus) |

| Engine | YANMAR 4TNV98T |

| Engine Type | Water-cooled Diesel, 4 Stroke, 4 Cylinder |

| Power | 62.5 KW / 2500RPM |

| Drive | 4-wheels Hydraulic Drive |

| Turning Mode | 2 Wheels/ 4 Wheels/ Crab Turn |

| Tyre | Solid Puncture Resistant Tires |

| Leg leveling | Automatic leveling system |

| Walking Speed | 0-10 KM/h |

| Working Speed | 24 Square Meters/Min |

| Construction type | Flat Concrete Surface, Slope/Double Slopes Concrete |

| Cleaning system | 3Mpa High power cleaning pump |

| Screed Width | 3.5m |

| Paving Mode | Hydraulic Screw Conveyor Paving |

| Vibrating System | 3500N Hydraulic eccentric vibrating system |

| Accuracy | 1.5mm |

| Fuel Tank Volume | 120L |

| Outline Dimension | 5400*4200*2150mm |

| Weight | 6300KG |

High Efficiency and Easy Operation

The S360 Laser Screed comes equipped with a versatile control handle that allows for easy and intuitive operation of all functions, making it a breeze to learn and use.

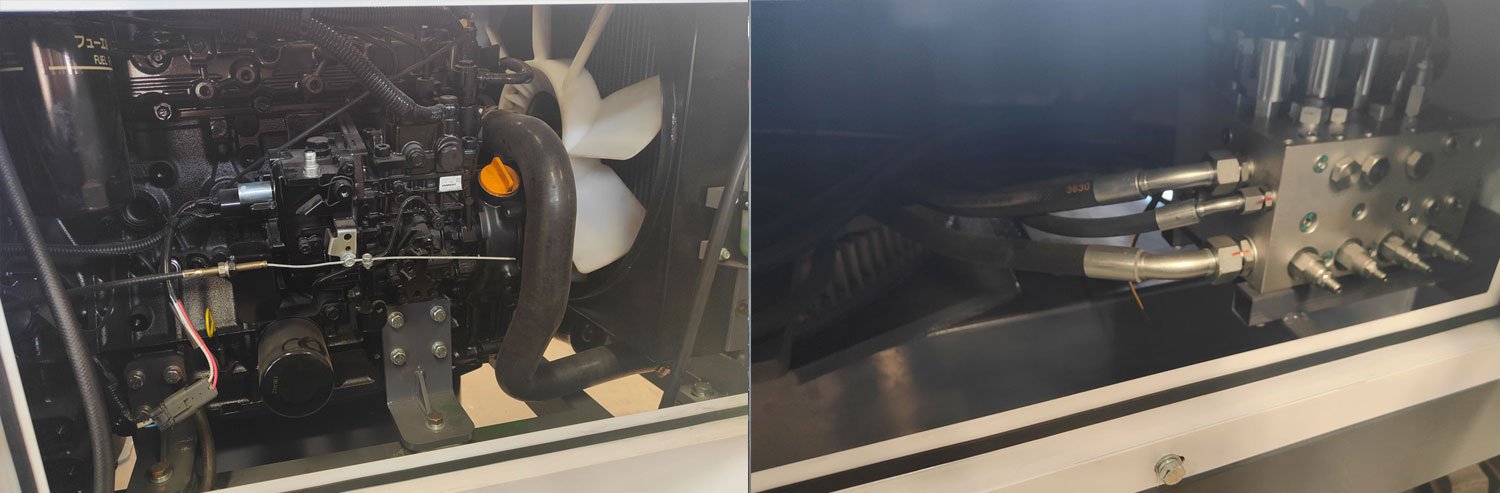

With its powerful and fuel-efficient Yanmar turbocharged diesel engine, the S360 is able to deliver high-performance results while consuming less fuel than other machines.

The machine’s intelligent variable pump is able to drive each action with precision, ensuring high efficiency and energy savings.

Precision and Accuracy

The S360 Laser Screed features an imported laser system that emits a stable and far-reaching beam, allowing for precise leveling and accurate results every time.

The machine’s intelligent control system ensures that the leveling mechanism is lowered in a controlled manner, allowing for a soft landing and increased accuracy in leveling surfaces.

The screed’s special vibration beam is designed with high-precision dynamic balancing, reducing vibrations and ensuring smooth and even surfaces.

Versatility and Durability

The S360 Laser Screed is equipped with hydraulic support legs that automatically adjust and level the machine with a single button press, making it easy to use on uneven surfaces.

The screed’s unique three-mode steering system allows it to navigate tight spaces and difficult terrain with ease.

With its sturdy construction and high-quality materials, including a specially-designed wear-resistant alloy steel screed blade, solid puncture-proof tires, and a high-pressure hydraulic cleaning system, the S360 is built to last and withstand even the toughest conditions.

Inquiry

Do you need S360 boom laser screed? If you have questions about it, please leave you contact in below from, we will reply to you in 24 hours

More Details

Equipped with a branded intelligent variable pump that can precisely drive each executing action with high energy efficiency and efficiency.

Equipped with a high-pressure hydraulic-driven cleaning water pump that can clean the machine body at any time.

Features of Laser Screed

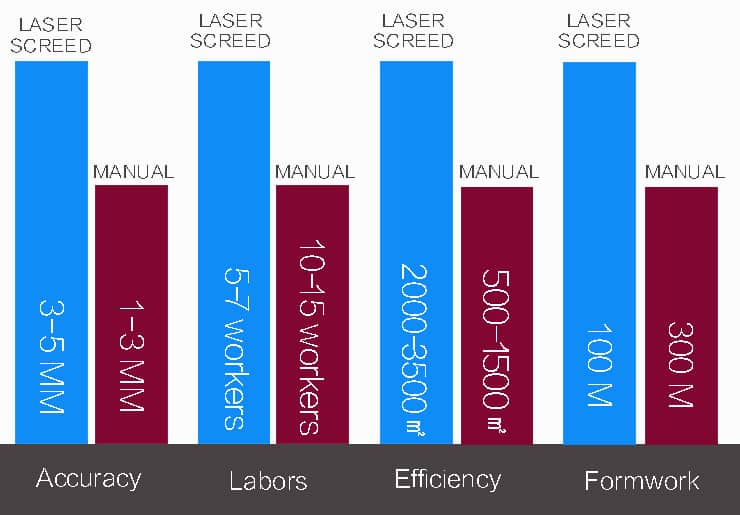

Comparison between HIKING laser screed and the traditional crafts

-

Reducing labor costs, improving efficiency doubled

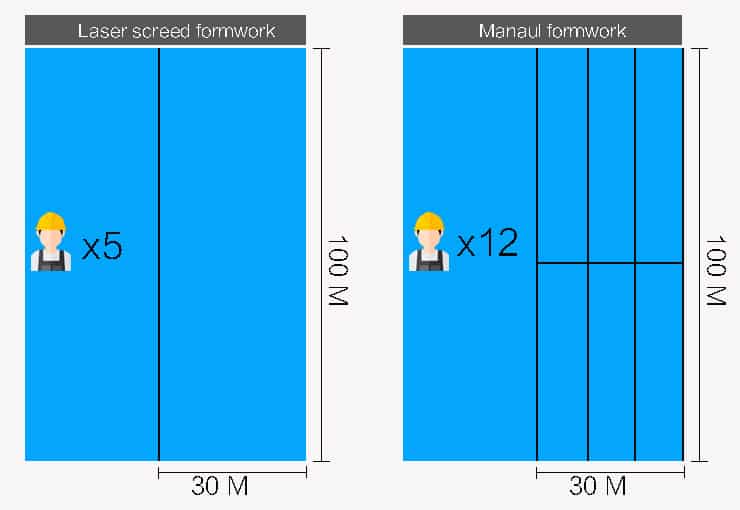

Using traditional construction process needs more workers for supporting template (channel), RBI, paving, needing about 20 persons. The construction area per day is 800-1500㎡.

Using HIKING laser concrete screed can reduce the overall number of people to 4-8 persons. It can also be operated by one person. The construction area per day can be improved to 2000㎡—3500㎡, greatly reducing the labor costs.

-

Laser point-to-point, high-precision, low error.

Traditional craft leveling needs to support templates to control surface elevation and pull control line. Elevation error is larger. Entire levelness and flatness of the floor can not be guaranteed.

Using laser point emitter is applicable to disposable paving in a large area. The laser measurement and control system controls the elevation anytime, it does not need to pull the control line when leveling, it does not also need to support side templates to control ground level, thus avoiding the elevation error caused by template (channel) shock during the construction process, also reducing the elevation error caused by Traditional artificial block formworks.

-

Better flatness and integrity

Traditional construction process needs one day for formworks and one day for pouring mercury, so they can only jump for construction from one piece to another, there is a large limitation here they can not do continuous operation, and there exists a bad integrity and it is easy to cumulative errors in construction joints.

HIKING laser concrete screed will have a greater efficiency and flatness for the disposable overall paving with a large area of floor. The completion of the entire floor will make a better ground integrity. The traditional construction process can not complete this.

The ground will be even more dense and uniform.frequency vibrator of 4000 times per minute will let the vibrator of leveling head produce an uniform high frequency vibration to make even more dense concrete floor.

Inquiry Us

IF you need to know more about the Laser screed, you can leave your contact in the below from, We will contact you in 24 hours.